Uncommon Projects

James Hoy and Alan Drumm founded Uncommon Projects in 2011. Today they create beautiful, bespoke freestanding and fitted furniture for homes across the country. We met with James and Alan over lunch and enjoyed a tour of their studio and factory.

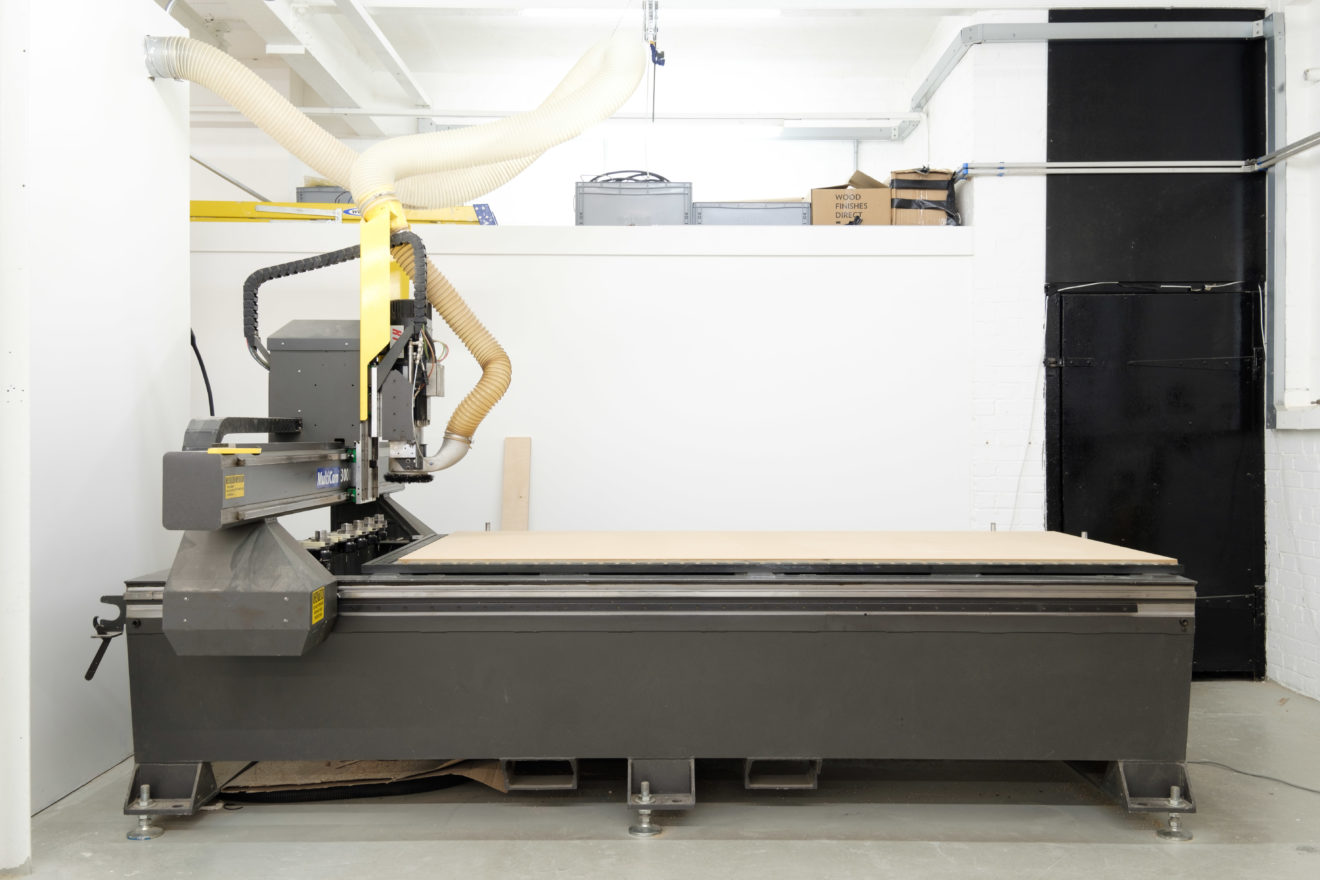

Alan and I were friends before Uncommon Projects and coincidentally each brought a property in London at around the same time. We were both disappointed with the quality and price of furniture available on the market and thought there must be a better way. We had no experience with solid wood and certainly wanted to avoid chipboard. So, initially, I attempted making ply shelving in my flat with a circular saw and hand router. It was good but not quite up to the quality I wanted. After a complete rebuild of his house Alan was looking to put in a new kitchen, so we decided to make one. We drew up each of the elements to be cut and output it on a CNC router. This immediately meant we didn’t have to follow the usual kitchen designer approach of joining together different standard size boxes to fill up the space. If we make a run of units, it usually has one top and one bottom and is made as a single 3D object. We loved the design freedom this gave us. This first kitchen was a success and we began to think we might be able to make something of this. We were in recession at the time and that meant a CNC machine came on the market at a price we could afford. We took a leap of faith and bought it. Though we worked day jobs alongside Uncommon Projects for the first couple of years, we now have a growing team, a full order book and have never really looked back!

Our biggest challenge is working with ply. The cross lamination gives a lot of benefits in terms of strength, versatility and durability, as well as being beautiful to look at! However, the thickness of each sheet does vary by as much as a millimetre each time. Great jointing and finishing are extremely important to us and the in-frame doors mean every detail of the carcass is always on show. Therefore, we had to redesign every new project right down to the finest detail. At first, we overcame this simply by drawing very carefully and methodically. We then put in systems and processes to help us cope. We are now carefully investing in software and technology that will support us but still allow us the flexibility to create original and bespoke design, as that is an important part of our DNA. The old adage ‘measure twice, cut once’ is still key though!

Our clients are really varied. At one end, last year we made a 16 metre wall of kitchen/workspace furniture for a Maggie’s Cancer Centre in Oldham which we’re really proud of. We frequently work with architects and contractors, but the core of our business would be kitchen and workspace furniture for 40ish professionals who want to make a home. They often come from design background or have an interest in mid-century modern furniture or architecture. Our furniture is built to last and is a choice for those who have grown out of the usual chipboard mass market options. So basically, our market is anyone who doesn’t want chipboard.

We believe plywood is a warm, natural and honest material. We want to give people furniture that will last and is made to suit them and no one else. That way it makes a home not a house.

I think we’re happy to consolidate what we have, for now …but we are starting to look at Uncommon Objects so watch this space!